As reported in a previous post, the mid- to late-teens saw a rise in a more enclosed body for production speedsters, so it was only natural that kit-built aftermarket speedsters progress to that. Hence, two arms of the sport-bodied speedster developed.

Coachbuilders that formerly built horse-driven carriages and whatnot were becoming an emerging supplier to the speedster-minded crowd who wanted to build their own contraption. Many companies made or franchised body designs that were initially fitted to the Ford Model T chassis, and later, to the Chevrolet 490. One such company was the Mercury Body Corporation of Louisville, Kentucky.

Mercury Body catalog cover. Image courtesy Jarvis Erickson collection

Mercury Design

Organized by Charles E. McCormick of Lexington, Kentucky, the initial patents were granted in late 1920 and early 1921 for innovations in body design. The initial objective was “to provide features whereby a Ford car may be so modified in appearance and so improved structurally as to combine simple, comfortable, and substantial qualities with pleasing streamline effects.”

The salient features of the Mercury body listed in the patent papers:

1. A lowered chassis using a dropped front axle and a bent frame to accommodate the rear axle.

2. A taper tail

3. Overall body shape that “greatly decreases the unavoidable head-on air resistance of the car”

Initial patent of the Mercury body, granted Nov. 30, 1920. image courtesy U.S. Patent Offc

This second patent image better shows the streamlined shape of the Mercury. (Compare this to the Morton & Brett patented body as illustrated in my “Everyman Speedster” post from June 7, 2019) U.S. Patent Offc.

Other details of the body revealed some innovation. The body pieces were die-stamped, a new process for this period. Eighteen-gauge steel panels were electrically seam-welded and built with two channels that attached to the bare chassis in four places. The floor was 14-gauge and covered with linoleum.

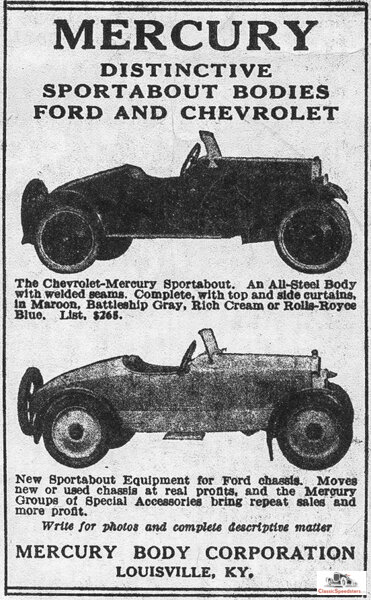

Magazine ad for the Mercury Sportabout from a July 1924 edition of Chilton’s Automobile Directory. image courtesy AACA Library

The earlier models did not have doors, but later models featured a 21” wide door on the passenger side only. The Fedders-type radiator provided twice the cooling capacity of the standard Ford unit, and it was housed within a solid nickel silver radiator shell. Louvers were cut into the engine cowl, and ventilators kept air flowing to the passengers. A well-made top was provided with side curtains to form a completely weatherproof enclosure. Attention to detail and quality materials were hallmarks of the Mercury body.

1921 Mercury catalog image illustrating the early-style top. Later-style tops had an additional bow to provide more headroom. Note the overall excellent build quality of this kit! image courtesy Jarvis Erickson collection

Manufacturing History

Mercury Body Corp opened for business on March 18, 1920, with its initial patent application filed at that time. It was incorporated by September of 1920 with a $100,000 capitalization, principal partners being C.E. McCormick, Guy Hugelet, and L.G. Pulliam. Motor Age reported in its Dec 23, 1920 issue that Mercury planned to employ 150 workers and build 6000 bodies per year at its Louisville factory. Mercury bodies were numbered, and although enumerated to almost 1600, it is believed that only 1065 total bodies were actually manufactured, 472 Ford bodies and 593 Chevrolet bodies. Less than 75 total examples exist today.

Note the chassis details in the photos above of this very illustrative ad. These photos are treasure for restoration artisans! image courtesy Jarvis Erickson collection

Although Mercury initially produced bodies only for Ford Model Ts, in 1923 they also made a body for the Chevrolet 490 chassis.

This flyer offered the Mercury body for the Chevrolet 490. image courtesy Jarvis Erickson collection

The Chevy had a wider wheel track, and thus the taper tail was given a boattail effect by virtue of spacers that filled that gap and connected the rear fenders to the body.

1926 Mercury Sportabout using a Chevrolet chassis. Note the spacers between the fender and the body, accentuating its tapered tail. Disc wheels were a shazam option of the times. photo taken by editor at 2017 Pinehurst Concours

Company Demise

The early 1920s limped along in recovery from a brutal world war that had chewed up a good part of Europe and wasted the capitalized world’s economies. Although relatively unscathed, the United States saw 1921 begin with a recession and progress to a depression by 1922. Following this, a mini-boom led to another economic slowdown in 1924-25. Choppy economic seas like this drowned many a company, and Mercury could not maintain its footing nor remain afloat. Automotive Industries in its June 25, 1925 issue reported that the newly-incorporated Mercury Body Company took over the Mercury Body Corporation for the purpose of rehabilitating its liquidity. Or maybe just to prepare the company for sale. In any case, Mercury was in trouble.

News item in the June 25, 1925 edition of Automotive Industries, p. 1155. image courtesy Horseless Carriage Foundation Library

The following year saw no improvement in Mercury’s prospects, and on July 22, 1926 Automotive Industries reported that the Jackson Body Company of Louisville, maker of hearses, had purchased the entire rolling stock of Mercury Body at a bankruptcy auction. At some point, this same fate was shared by all aftermarket suppliers of coachbuilt kit bodies for the Model T and Chevrolet.

Mercury Body purchased at bankruptcy auction as reported in Automotive Industries, July 22, 1926, p.150 image courtesy HCF Library

By 1928 Jackson Body of Louisville had also ceased operating. Such were the times…

Adios to a great little speedster! image courtesy Jarvis Erickson collection

Jarvis Erickson’s extensive scholarship in the world of Ford Model T speedsters has made him a renowned historian of the Mercury Body Corporation. Many thanks to him for his contributions to archiving and preserving the Mercury story!